中控通用控制系统UCS-Nyx获国际知名行业期刊IAA重磅报道

中控通用控制系统UCS-Nyx获国际知名行业期刊IAA重磅报道

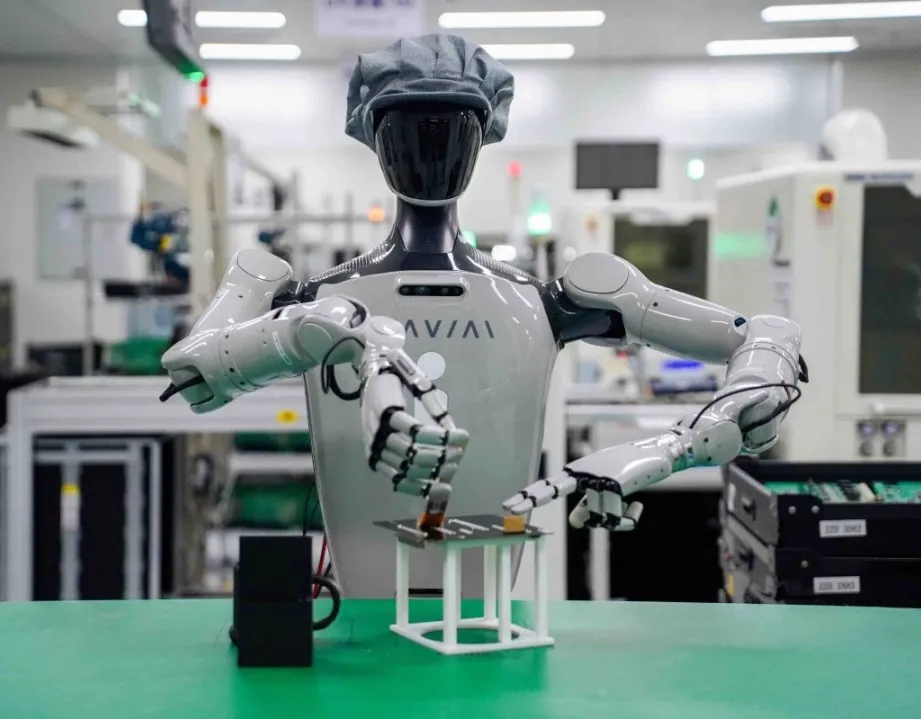

图源:官方网站

Source of the picture: official website

近日,中控通用控制系统UCS(Universal Control System)产品Nyx获得国际知名行业期刊《Industrial Automation Asia》(IAA)的重磅报道。IAA作为工业自动化领域的权威刊物,在全球范围内具有广泛影响力,此次报道彰显了中控技术的创新实力和技术成果在国际行业领域受到广泛关注,进一步扩大了中控技术在全球工业AI领域的品牌影响与优势地位,为公司未来国际化战略实施提供了有力支持。

Recently, SUPCON's Universal Control System (UCS) product, 'Nyx,' was prominently featured in Industrial Automation Asia (IAA), a globally recognized and influential journal in the industrial automation sector. This recognition underscores SUPCON's innovative capabilities and technological achievements, which have garnered significant attention in the international industry. The publication further enhances SUPCON's brand influence and competitive position in the global industrial AI field. Additionally, it serves as a strong endorsement of the company's ongoing internationalization strategy.

以下为IAA杂志刊登内容:

The following is content published in IAA Magazine:

SUPCON Universal Control System Nyx: Reinvent DCS In The AI Era

UNLEASHING THE INFINITE POTENTIAL OF FUTURE AUTOMATION

Artificial intelligence, Big Data, and Cloud Computing are the pillars of the fourth industrial revolution, contributing unparalleled potential for major innovations of control systems. The future of automation hinges upon the robust IT infrastructure, mature cloud computing technologies, fully networked smart equipment, and most importantly, a simplified flat architecture, which can significantly reduce the CapEx of new projects. Adopting cutting-edge technologies can optimize performance, reduce system footprint, accelerate commissioning, reduce downtime, increase security, and boost overall efficiency.

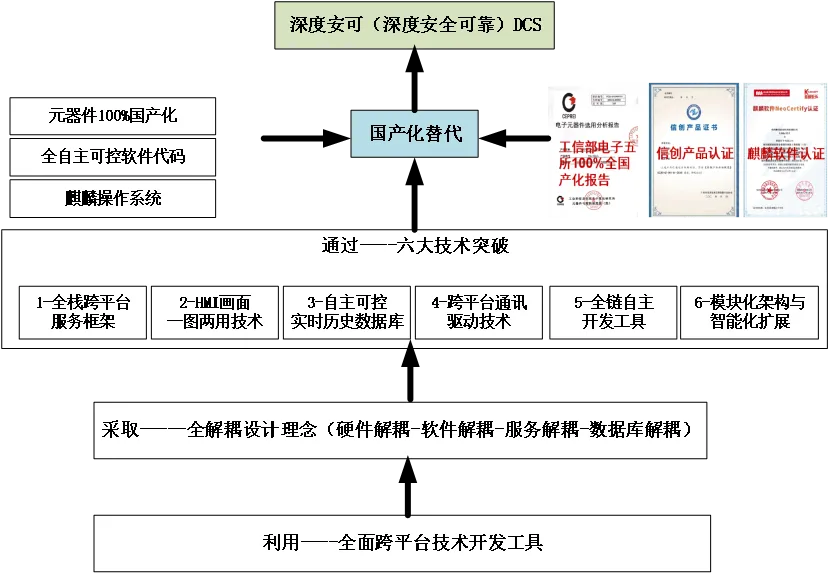

To address the constraints of traditional distributed control systems-rigid hierarchy, purpose-built hardware, and limited computing power, SUPCON has invented the Universal Control System (UCS). This revolutionary innovation redefines the control system with its software-defined, fully digital and cloud-native architecture, marking a significant leap from the DCS (Distributed Control System) architecture that has prevailed for nearly 50 years.

Nyx, SUPCON's first UCS product, exemplifies this innovation and delivers exceptional value through its advanced components: a robust control data center, a high-speed deterministic optical industrial network, and advanced Ethernet APL field connection technology.

CONTROL DATA CENTER

As the control center of Nyx, NyxOS is a high-performance cloud-based real-time operating system engineered for demanding real-time control applications. It offers a robust and secure environment for real-time task scheduling and execution. By adopting containerization, NyxOS features flexible expansion, rapid deployment and streamlined maintenance & upgrades. Nyx also introduces 1:N redundancy for all control services and on-demand auto-generated backup services. With a strong emphasis on "Security by Design," Nyx complies with the Secure Development Lifecycle (SDL), and incorporates Zero Trust Architecture, Secure Container Protection and Trusted Computing to achieve a significantly higher security level than traditional DCS systems.

DETERMINISTIC OPTICAL INDUSTRIAL NETWORK

Utilizing high-speed optical networks, deterministic scheduling, IPv6, and self-organized software-defined communication, Nyx creates a simplified network architecture that saves over 90% of copper instrument cables and installation space while improving communication performance by more than 10 times.

ETHERNET APL CONNECTED FIELD

Nyx offers Zone 2 intrinsically safe field junction boxes and APL modules, and enables field instrument IP addressing, increasing communication speed by more than 100 times. It facilitates total digital field sensing and acting, simplifies field data access, and enhances intelligent data interconnection. APL instruments in Nyx are much easier to install, commission, and maintain. Considering APL's advantages in reducing copper cable usage and installation costs, SUPCON is now actively building an APL products ecosystem and sharing know-how of APL technology with the traditional instrument companies.

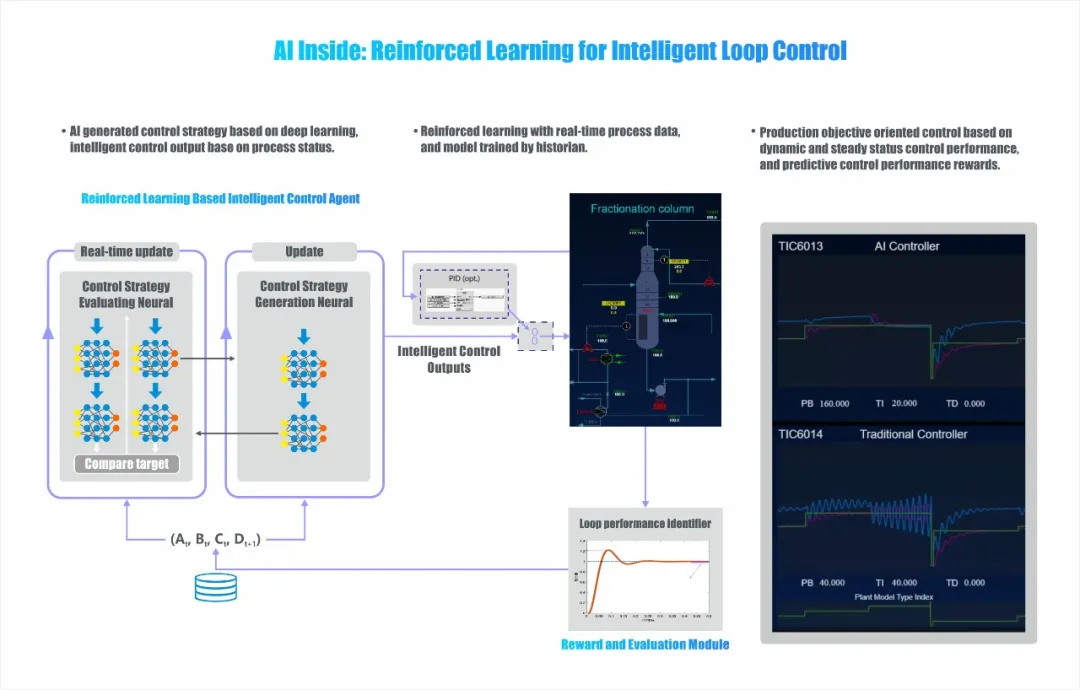

AI-INSIDE BRINGS AI POWER TO

REAL-TIME CONTROL

Nyx integrates AI technology and provides functions such as AI code generation and reinforcement learning-based AI-PID. This enables highly autonomous plant operation and improves plant productivity. For the first time, GPU computing power is introduced in the control system, and with the advanced programming languages like C++ and Python, Nyx has broken though the limit of computing power and supports the execution of more advanced AI algorithms in the control system. This empowers the process industry users to achieve AI-based intelligent control and predictive maintenance, improve production efficiency, and realize digital transformation.

AI-PID is an intelligent control function based on reinforcement learning, consisting of four components: Traditional Control PID, Control Effect Evaluation And Reward/ Punishment Mechanism, Training Database, and Control Strategy Neural Network. The initial control strategy model is generated by the Traditional Control PID. During real-time operation, the Control Effect Evaluation And Reward/ Punishment Mechanism evaluates the control effect and feeds back to the reinforcement learning agent. The agent judges the pros and cons of the control parameters according to the feedback, updates the training database, and iterates the parameters of the control strategy. Compared with the traditional PID tuning, AI-PID offers greater stability and adaptation to multiple working conditions, allowing continuous optimization of control effects for the production process in a more reliable and rapid manner.

Nyx redefines industrial automation with groundbreaking capabilities, including the unprecedented computing power, advanced control algorithms, streamlined operations and maintenance, and paves a pathway to the smart enterprise prioritizing safety, quality, sustainability and efficiency. It's pilot projects have already validated the design, achieving 90% reduction in cabinet space, 80% reduction in copper cable usage, and 50% reduction in project timeline. In the future, SUPCON will continue to explore new possibilities of automation, actively adopt cutting-edge technologies such as AI and ML, and continuously accelerate the digital transformation for the process industry.

我要收藏

点个赞吧

转发分享

评论排行